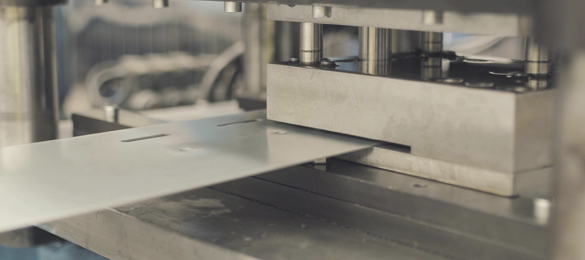

Axial Structural Solutions is in charge of the manufacture, reception and pre-assembly of different components of the structural system designed and planned by our Engineering Department.

From our central office we control the traceability of the products and verify the manufacturing situation all the time from the purchase of raw materials to the delivery to the clients, allowing us to measure the installation equipment and feedback to the client throughout the process.

All our structural systems bear the CE Marking conferred by UNE EN1090 Standard. Axial designs and manufactures the technical solution that best fits the project of each client. Our structures are of high quality and are provided with 25 years warranty.